Introduction

In the car detailing industry, using the right equipment is crucial to ensure efficient and effective cleaning. One such essential tool is a heavy-duty chemical-resistant sprayer. These sprayers are designed to withstand harsh chemicals and provide consistent spray patterns, making them ideal for various car detailing tasks. This comprehensive guide will walk you through everything you need to know about heavy-duty chemical-resistant sprayers, their types, selection criteria, maintenance, and safety tips.

Section 1: Importance of Chemical-Resistant Sprayers

Car detailing often involves using strong chemicals, such as degreasers and solvents, to remove dirt, grime, and stains from vehicles. Standard sprayers may not be able to handle these chemicals, leading to premature wear and tear. Chemical-resistant sprayers, on the other hand, are specifically designed to withstand the corrosive nature of these substances, ensuring longevity and consistent performance. They provide car detailers with a reliable and durable tool for their cleaning needs.

- By using chemical-resistant sprayers, car detailers can ensure the longevity of their equipment while maintaining consistent performance. These sprayers are specifically built to withstand the corrosive effects of chemicals, preventing premature wear and tear. They are constructed using materials such as polyethylene, which offer excellent resistance to chemical corrosion.

- Using a chemical-resistant sprayer provides car detailers with peace of mind knowing that their equipment can withstand the harsh chemicals used in the industry. It eliminates the risk of sprayer malfunction due to chemical exposure, which can lead to leaks, clogs, or spray pattern irregularities.

- Moreover, chemical-resistant sprayers offer better control and efficiency in the application of cleaning agents. They provide consistent spray patterns, allowing detailers to evenly distribute the chemicals on the vehicle’s surfaces. This ensures thorough coverage and effective cleaning, resulting in high-quality detailing work.

Overall, the importance of chemical-resistant sprayers in the car detailing industry cannot be overstated. They provide durability, reliability, and efficiency when working with aggressive cleaning agents. Car detailers who invest in these sprayers can deliver exceptional results to their clients while minimizing the risk of equipment failure.

Section 2: Understanding Heavy-Duty Chemical-Resistant Sprayers

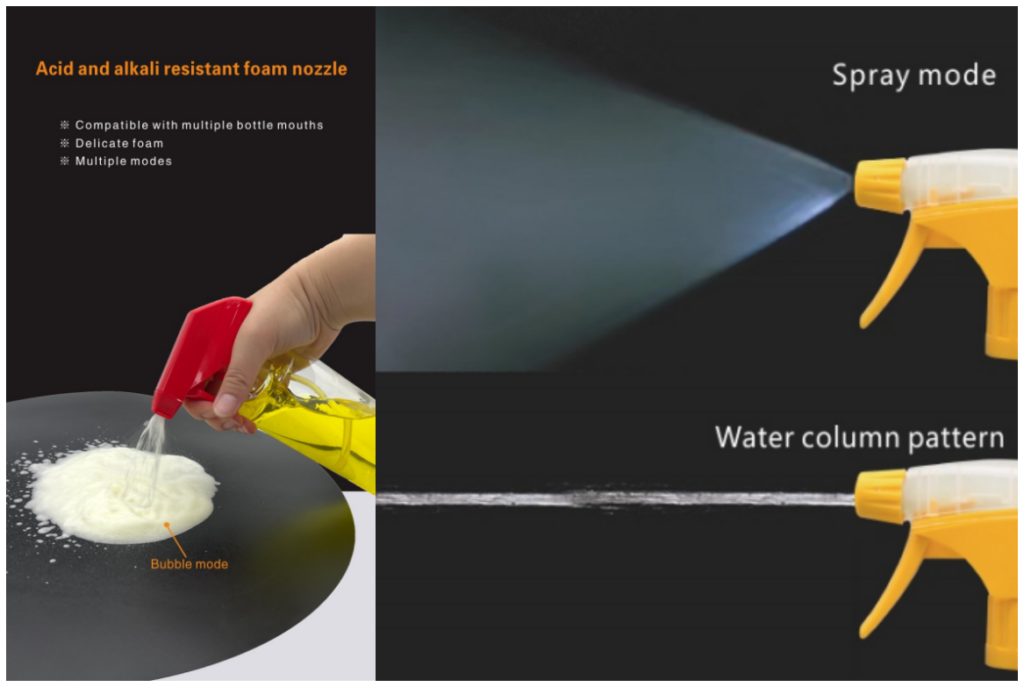

Heavy-duty chemical-resistant sprayers are specifically engineered to withstand the corrosive nature of various car detailing products. Unlike regular sprayers, these sprayers are built with durable materials that resist chemical degradation. They feature high-quality seals, chemical-resistant hoses, and full nozzle heads that ensure long-lasting performance and prevent leaks. These sprayers are capable of handling a wide range of chemical formulations, making them an essential tool for car detailing professionals.

Images source: Heavy-Duty Chemical-Resistant Sprayer

Here’s some information to help you understand heavy-duty chemical-resistant sprayers in more detail:

- Chemical Resistance: Heavy-duty sprayers are made from materials that are resistant to a wide range of chemicals commonly used in car detailing, such as degreasers, wheel cleaners, tar removers, and upholstery cleaners. They are typically constructed with components like Viton seals, chemical-resistant hoses, and reinforced tanks that can handle the corrosive nature of these chemicals without degradation.

- Durability: These sprayers are built to withstand the demanding conditions of the car detailing environment. They often have robust construction using materials like polyethylene, and polypropylene for the tank and handle. This ensures that the sprayer can withstand impacts and rough handling, and resist leaks or cracks.

- Adjustable Nozzles: Chemical-resistant sprayers often come with adjustable nozzles that allow detailers to control the spray pattern and intensity. This feature enables them to apply the chemicals precisely where needed, whether it’s a wide fan spray for larger areas or a focused stream for targeting specific spots.

- Capacity: These sprayers come in a range of tank capacities to accommodate various detailing tasks. Smaller sprayers, with capacities of around 500 ml, are suitable for spot cleaning or targeted applications, while larger tanks with capacities of up to 1000 ml or more are ideal for bigger detailing jobs that require extended use without frequent refilling.

- Versatility: Chemical-resistant sprayers are not limited to car detailing; they can be used in various other industries as well. Their chemical resistance and durability make them suitable for applications in agriculture, landscaping, pest control, and industrial cleaning, among others.

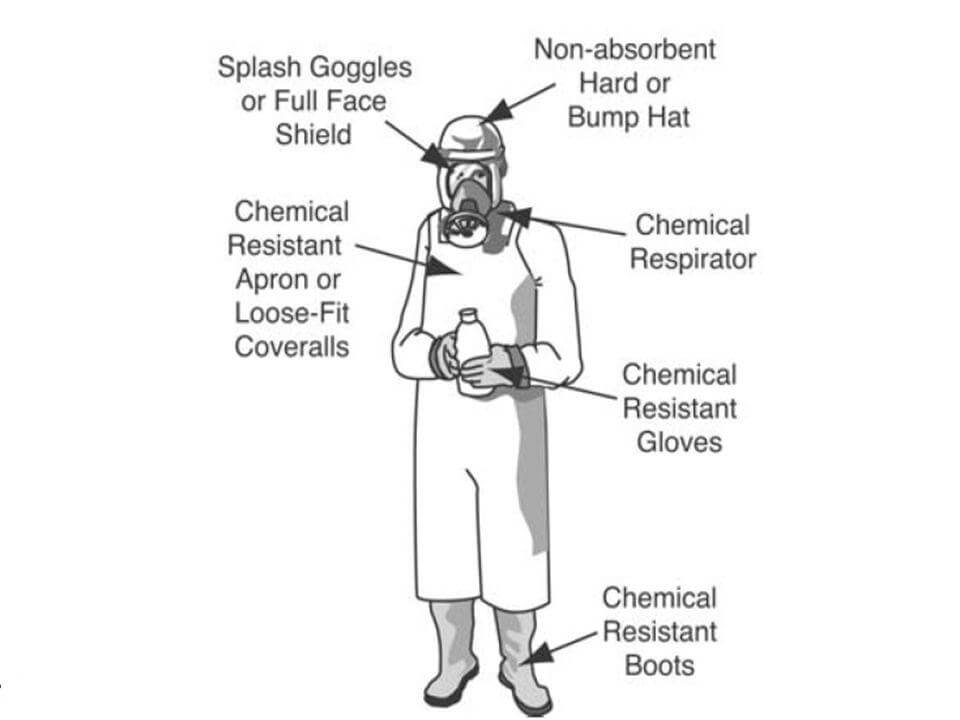

- Safety Considerations: When working with chemical-resistant sprayers, it’s important to prioritize safety. Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and a respirator, especially when handling concentrated chemicals. Follow the instructions provided by the chemical manufacturers and the sprayer manufacturer to ensure safe and proper usage.

Images source: safety considerations

Overall, heavy-duty chemical-resistant sprayers are valuable tools in the car detailing industry. They offer durability, chemical resistance, and adjustable spraying features, allowing detailers to effectively and safely apply various chemicals to clean, protect, and maintain vehicles.

Section 3: Advantages and Applications

Heavy-duty chemical-resistant sprayers offer several advantages and have various applications in the car detailing industry. Here are some key advantages and applications to consider:

Advantages:

- Chemical Resistance: Heavy-duty chemical-resistant sprayers are designed to withstand the corrosive nature of various detailing chemicals. They are constructed using materials that can resist degradation and damage caused by aggressive chemicals, ensuring durability and longevity.

- Versatility: These sprayers are suitable for handling a wide variety of detailing chemicals, including degreasers, wheel cleaners, interior cleaners, bug removers, and other specialized products. They allow detailers to apply different products effectively, reducing the need for multiple sprayers.

- Precise Application: Heavy-duty sprayers often feature adjustable nozzles or spray patterns, enabling detailers to control the spray area and the amount of product applied. This precision allows for targeted application, reducing waste and ensuring even coverage.

- Durability: The construction of heavy-duty sprayers is robust and designed to withstand the demanding conditions of the car detailing industry. They are built to be resistant to impacts, drops, and other potential sources of damage, ensuring they can withstand frequent use.

- Ergonomics: Many heavy-duty sprayers are ergonomically designed, providing comfortable grip handles and user-friendly triggers. This design feature reduces hand fatigue during prolonged use, improving efficiency and productivity.

Applications:

- Exterior Cleaning: Heavy-duty chemical-resistant sprayers are commonly used for exterior cleaning tasks in car detailing. They are effective for applying various cleaning solutions, such as degreasers, wheel cleaners, bug and tar removers, and pre-wash treatments. The adjustable spray patterns help cover larger areas like the car body, wheels, and undercarriage efficiently.

Images source: DECON PRO IRON REMOVER AND WHEEL CLEANER

- Interior Detailing: These sprayers are also suitable for interior detailing tasks. They can be used to apply upholstery cleaners, carpet shampoos, and fabric protectants. The sprayer’s adjustable spray patterns and pressure control allow for precise application on seats, carpets, door panels, and other interior surfaces.

Images source: FOAMING CITRUS FABRIC CLEAN

- Engine Bay Cleaning: Heavy-duty sprayers are commonly employed for cleaning the engine bay area. With their chemical resistance, they can handle degreasers and engine cleaners effectively. The sprayers help dislodge dirt and grime from engine components, allowing for thorough cleaning without damaging sensitive parts.

Images source: Meguiar’s D1801

- Spot Cleaning and Stain Removal: For targeted cleaning and stain removal, heavy-duty sprayers are ideal. They can be used to apply spot removers or concentrated cleaning solutions to specific areas, such as stubborn stains on glass. The sprayers provide control over the spray pattern and pressure, enabling precise application on small, localized areas.

Images source: STREAK FREE WINDOW CLEAN GLASS CLEANER

- Spraying protective coatings and sealants: These sprayers distribute coatings and sealants evenly, creating a durable layer of protection and enhancing the vehicle’s shine and longevity.

Images source: CARBON FLEX VITALIZE QUICK DETAIL SPRAY & SEALANT CERAMIC COATING BOOSTER

Section 4: Factors to Consider When Choosing a Heavy-Duty Chemical-Resistant Sprayer

When choosing a heavy-duty chemical-resistant sprayer for the car detailing industry, there are several important factors to consider. Here are some key points to keep in mind:

- Chemical Compatibility: Ensure that the sprayer is specifically designed to handle the chemicals used in car detailing, such as cleaning solutions, degreasers, or other automotive chemicals. Chemical resistance is crucial to prevent damage or deterioration of the sprayer.

- Material Construction: Look for sprayers made from high-quality materials that can withstand harsh chemicals and rigorous use. Common materials used in chemical-resistant sprayers include polyethylene and polypropylene. Choose a sprayer with components that are resistant to corrosion and wear.

- Nozzles and Spraying Models: Different spraying models (such as fan, cone, or stream) and nozzle types offer versatility in application. Choose a sprayer that provides interchangeable nozzles or adjustable nozzles to accommodate various car detailing tasks, such as applying the foam, spot cleaning, or rinsing.

- Durability and Reliability: Look for sprayers from reputable brands known for their durability and reliability. Read customer reviews provided to ensure that you’re investing in a long-lasting sprayer.

- Ergonomics and Comfort: Car detailing often involves extended periods of use, so consider the ergonomics and comfort features of the sprayer. Look for a sprayer with a comfortable grip, and lightweight construction to reduce fatigue during prolonged use.

- Accessories and Compatibility: Consider any additional accessories or attachments that may be required for your car detailing tasks, such as foam cannons, or specialized brushes. Ensure that the sprayer is compatible with these accessories or that they are readily available.

Image source: THE GALACTIC INFUSED FOAM & SHINE TIRE KIT

- Price and Value: Compare the features, quality, and price of different sprayers to find the best value for your budget. Keep in mind that investing in a higher-quality, chemical-resistant sprayer may be more cost-effective in the long run due to its durability and performance.

By considering these factors, you can choose a heavy-duty chemical-resistant sprayer that meets your car detailing requirements and withstands the demanding conditions of the industry.

Section 5: Tips for Proper Usage and Maintenance

Proper usage and maintenance of heavy-duty chemical-resistant sprayers in the car detailing industry are essential to ensure their longevity and efficient operation. Here are some tips to help you with that:

- Read the Instructions: Familiarize yourself with the manufacturer’s instructions and guidelines provided with the sprayer. This will help you understand its specific features, limitations, and maintenance requirements.

- Wear Protective Gear: Always wear appropriate personal protective equipment (PPE) when handling chemicals and operating the sprayer. This includes gloves, goggles, and a respirator if necessary, to protect yourself from potentially harmful substances.

Images source: safety considerations

- Use the Right Chemicals: Ensure that you are using chemicals that are compatible with the sprayer’s chemical-resistant construction. Consult the manufacturer’s recommendations or product labels to verify compatibility. Using incompatible chemicals can damage the sprayer and compromise its effectiveness.

- Use a small funnel: To ensure liquids do not spill, you can use a small funnel by following these steps:

- Choose the right size: Select a small funnel that is suitable for the volume of liquid you need to pour. The funnel should have an opening wide enough to accommodate the liquid without causing an overflow.

- Position the funnel correctly: Place the funnel securely on top of the container or receiving vessel where you want to pour the liquid. Ensure that the funnel sits snugly and doesn’t wobble or tip over during the pouring process.

- Pour slowly and steadily: Pour the liquid into the funnel in a controlled manner, maintaining a slow and steady flow. Avoid pouring too quickly as it can cause splashing or overflowing, defeating the purpose of using the funnel.

- Monitor the liquid level: Keep an eye on the liquid level inside the funnel and the receiving vessel. Slow down or pause pouring if the liquid is approaching the funnel’s capacity or the vessel’s maximum fill line to prevent spillage.

Remember, using a small funnel can be an effective way to ensure precisely and controlled pouring, minimizing the risk of spills or wastage.

- Dilution Ratios: Follow the recommended dilution ratios for the chemicals you are using. Improper dilution can lead to inadequate cleaning or excessive wear on the sprayer. Use measuring tools or containers to ensure accurate dilution.

Images source: Dilute

- Storage: Store the sprayer in a clean, dry, and well-ventilated area, away from direct sunlight or extreme temperatures. Proper storage prevents corrosion and deterioration of the sprayer’s materials.

- Handle with Care: Treat the sprayer with care to prevent accidental damage. Avoid dropping or mishandling the sprayer, as it can lead to cracks or breakages. Be mindful of the wand and nozzle, as they are sensitive components that require proper handling.

Conclusion:

Heavy-duty chemical-resistant sprayers play a crucial role in the car detailing industry, ensuring the efficient and effective application of cleaning solutions and coatings. By understanding the features, advantages, and factors to consider when selecting a sprayer, you can make an informed decision that meets your requirements. Remember to follow proper usage and maintenance practices to prolong the lifespan of your sprayer. Consulting industry professionals to find the one that suits your needs and helps you achieve exceptional results in car detailing applications.